2021 High quality Asphalt Saw Blade - 10 Inch 250mm Continue Rim Ceramic Tile Saw Blades -Sinodiam

2021 High quality Asphalt Saw Blade - 10 Inch 250mm Continue Rim Ceramic Tile Saw Blades -Sinodiam Detail:

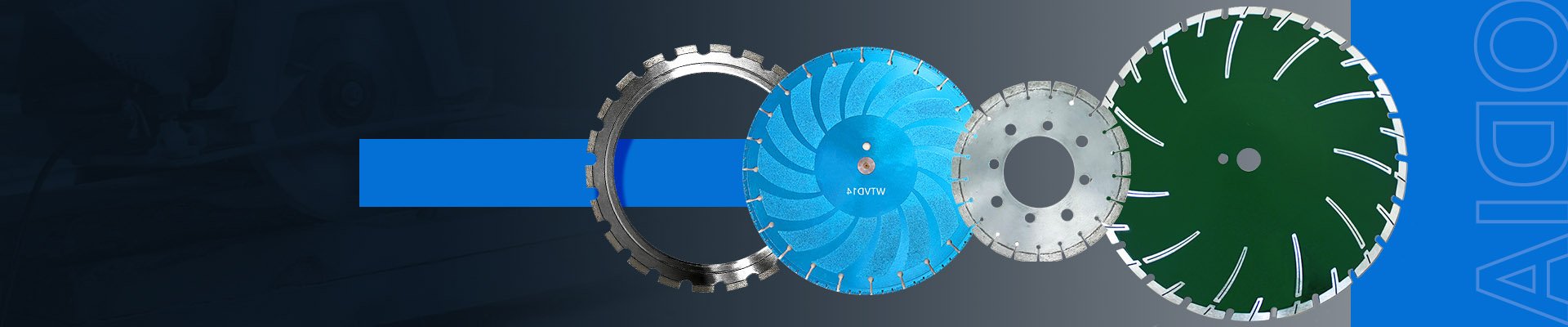

10 Inch 250mm Continue Rim Ceramic Tile Saw Blades

Description

| Process: | Hot Pressing | Quality Grade: | Premium Quality |

|---|---|---|---|

| Diameter: | 10″ | Segment Height: | 10mm |

| Arbor: | 7/8-5/8″ | Color: | Gold |

| Package: | Chamshell, Skin Card, White Box, Color Box | Type: | Continue Rim Ceramic Tile Diamond Cutting Blade |

| High Light: |

10 Inch 250mm Ceramic Tile Saw Blades, Continue Rim Ceramic Tile Saw Blades, Continue Rim 10 Inch Tile Saw Blade |

||

10 Inch Continue Rim Ceramic Tile Saw Blade Premium Quality with 5/8 Inch Arbor

1. Continue Rim Ceramic Tile Saw Blades Description

This 10"(250mm) hot-pressed general purpose diamond blade is a kind of sintered diamond blade which consists of a solid steel core surrounded by a circular pattern of diamond cutting teeth. By means of Sinodiam's professional hot-pressed diamond tool manufacturing technology, the cutting teeth are made from pretty hard diamond and a certain proportion of metal powder that are pressed together at high temperatures. In addition, this diamond saw blade will be subject to high-temperature and high-pressure sintering through our pioneering diamond tool hot pressed sintering process.

SinoDiam SPTC series tile cutting diamond blade is desgined to provide fast, smooth cutting in a variety of ceramic tile, porceline tile with fast cutting and no chips, can be used wet or dry.

2. Specificaiton of SPJT series

| Code # | Diameter (mm) |

Diameter (Inch) |

Arbor (mm) |

Arbor (Inch) |

Segment Width (mm) |

Segment Width (Inch) |

Segment Height (mm) |

Segment Height (Inch) |

| SPTC4 |

100 | 4” | 22.23-15.88 | 7/8-5/8" | 1.5 | .060" | 10 | .395” |

| SPTC4.5 |

115 | 4.5" | 22.23-15.88 | 7/8-5/8" | 1.5 | .060" | 10 | .395” |

| SPTC5 |

125 | 5” | 22.23-15.88 | 7/8-5/8" | 1.5 | .060" | 10 | .395” |

| SPTC6 |

150 | 6" | 22.23-15.88 | 7/8-5/8" | 1.9 | .075" | 10 | .395” |

| SPTC7 |

180 | 7” | 22.23-15.88 | DM-7/8-5/8" | 1.9 | .075" | 10 | .395” |

| SPTC8 |

200 | 8" | 22.23-15.88 | 7/8-5/8" | 1.9 | .075" | 10 | .395” |

| SPTC9 |

230 | 9” | 22.23-15.88 | DM-7/8-5/8" | 2.2 | .085" | 10 | .395” |

| SPTC10 |

250 | 10" | 22.23-15.88 | 7/8-5/8" | 2.2 | .085" | 10 | .395” |

3. Character

- Sintered Diffusion Bonded.

- Use supreme quality diamond for fast cutting porcelain tile, ceramic tile, granite, marble, slate, terrazzo, engineered stone and similar materials.

- Laser-cut J-Shape slots are used for cooling the blade and removing dust/slurry, which greatly improves cutting performance.

- Thin (1.5mm) cutting rim improves cutting performance and results in the best cut.

- Can be used for dry cut and wet cut. Wet cut provides a better performance.

4. Recommeded Materials

- Great for porceline, ceramic and most nature stones

5. Worked on

For use on electric circular saws, tile saws, and right angle grinders.

6. Target Customer

Pro tile cutting, great value for rental, homeowner and general contractor usage

7. Other Notes

- Arbor can be customized;

- Paint color can be customized;

- Prviate label can be provided;

- Package can be customized.

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for 2021 High quality Asphalt Saw Blade - 10 Inch 250mm Continue Rim Ceramic Tile Saw Blades -Sinodiam , The product will supply to all over the world, such as: Turkey, Nairobi, Finland, With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!