12mm Aligned Diamond Segments Concrete Diamond Saw Blade

12mm Aligned Diamond Segments Concrete Diamond Saw Blade

Description

| Process: | Laser Welded | Quality Grade: | Supreme Quality |

|---|---|---|---|

| Diameter: | 12″, 14″, 16″, 18″, 20″, 24″ | Size: | 300mm, 350mm, 400mm, 450mm, 500mm, 600mm |

| Inner Hole: | 1″-20mm | Color: | Customize |

| Package: | White Box, Color Box | Type: | Supreme Aligned Diamond General Purpose Diamond Blade |

| High Light: |

12mm Aligned Diamond Saw Blade, 12mm Aligned Diamond Saw Blades, 16 Inch 400mm Concrete Diamond Saw Blade |

||

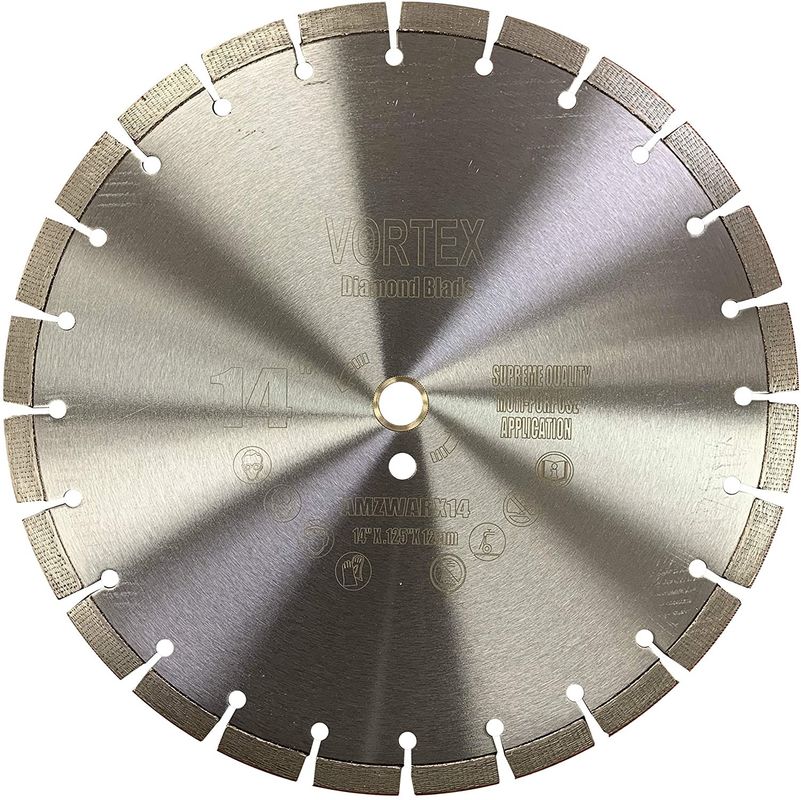

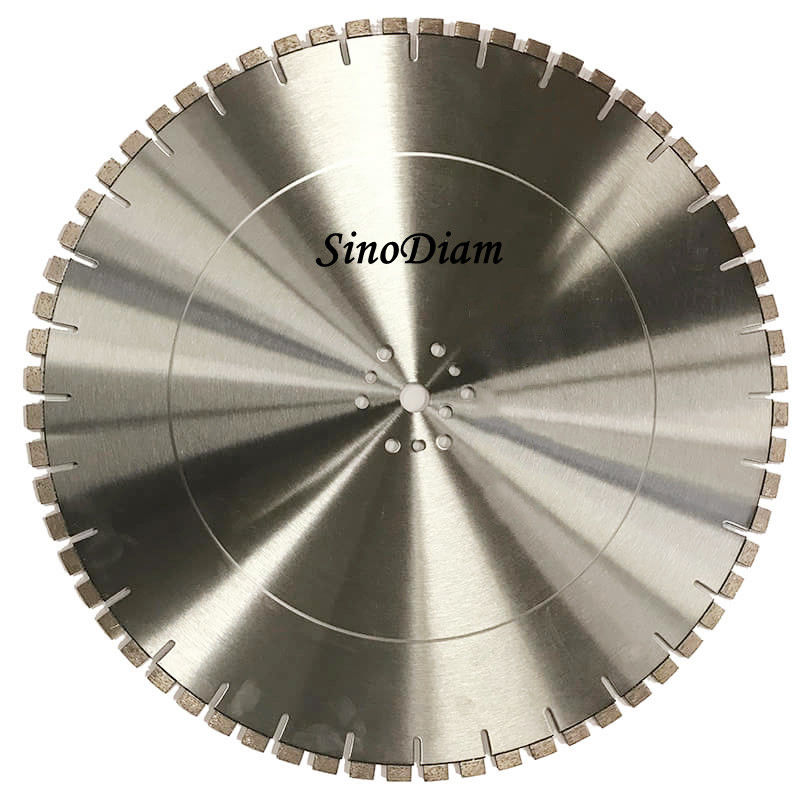

Laser Welded 12mm Concrete Diamond Saw Blade Supreme Quality Aligned Diamond Segments

1. Concrete Diamond Saw Blade Description

Laser welding is generally recognized as being the safest and most secure method of attaching the diamond and the bond to the rim. The energy from the laser melts and combines the metal of the diamond segment and the steel core creating a stronger weld, which can hold the segments even in high temperatures. It is a very precise process, targeting only the area of the blade being welded and so reducing the risk of any other part being affected by the intense heat involved

Laser welded diamond blade is used in construction industry mainly, especially in concrete cutting. Some concrete contains steel bars, the temperature of diamond segments goes up quickly when cutting the steel bars in concrete, the diamond blade segments may drop, it is very dangerous to the operators.

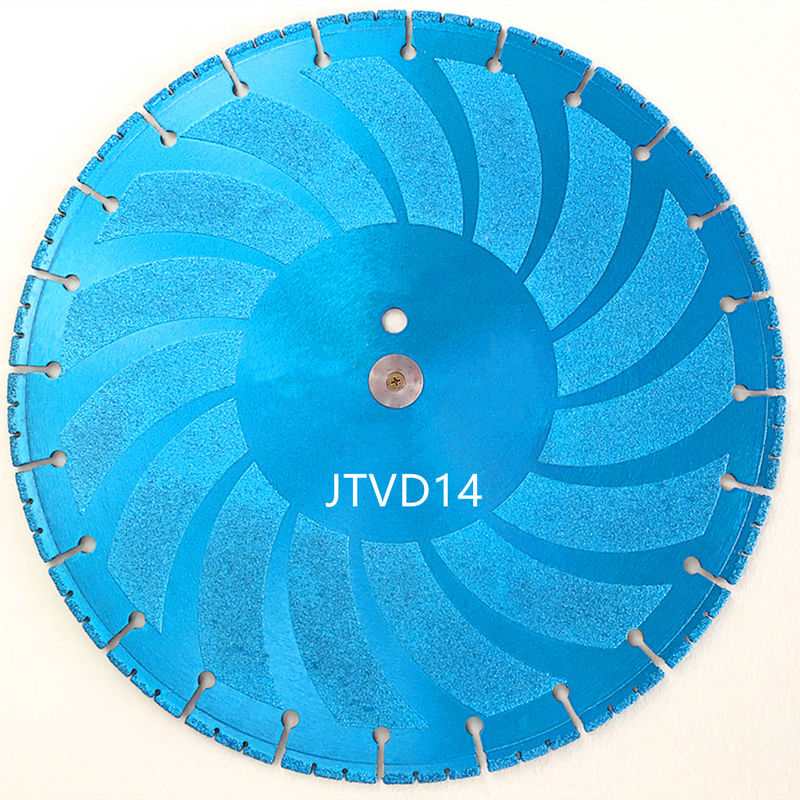

SinoDiam JTSX series general purpose diamond blade is a kind of laser welded diamond blade which consists of a solid steel core surrounded by a circular pattern of diamond cutting teeth. JTSX series is the generation in patterned diamond technology where the actual diamonds are precisely arranged and aligned in the segment. This patented technology delivers the maximum product consistency and significantly improves both cutting speed and blade life. Designed for cutting hard materials like cocnete, masonry, brick, block, they can even cut green concrete and asphalt with efficiency .

2. Specificaiton of JTSX series

| Code # | Diameter (mm) |

Diameter (Inch) |

Arbor (mm) |

Arbor (Inch) |

Segment Width (mm) |

Segment Width (Inch) |

Segment Height (mm) |

Segment Height (Inch) |

| JTSX12

|

300 | 12″ | 25.4-20 | 1″-20mm | 2.8 | .110″ | 12 | .470” |

| JTSX14 | 350 | 14″ | 25.4-20 | 1″-20mm | 3.2 | .125″ | 12 | .470″ |

| JTSX16 | 400 | 16″ | 25.4-20 | 1″-20mm | 3.2 | .125″ | 12 | .470″ |

| JTSX 18

|

450 | 18″ | 25.4 | 1″ | 3.6 | .140″ | 12 | .470″ |

| JTSX 20

|

500 | 20″ | 25.4 | 1″ | 3.6 | .140″ | 12 | .470″ |

| JTSX 24

|

600 | 24″ | 25.4 | 1″ | 3.6 | .140″ | 12 | .470″ |

3. Character

- Laser Welded.

- Medium Hard Bond

- 12mm Segmented Height.

- Fast agressive cutting in concrete, masonry, stone, building materials, even cut green concrete and asphalt.

-

Can be used in Dry and Wet.

-

Great for pro contractors who encounter a variety of jobs throughout the day..

4. Recommeded Materials

- Great for Concrete, Brick, Block.

5. Worked on

For use on high speed saws, masonry saws and low horse power walk behind saw.

6. Target Customer

Great for rental or pro contractors.

7. Other notes

- Abror can be customized;

- Paint color can be customized;

- Privide Lable can be provided;

- Package can be customized.

- The OSHA has strict regulations regarding silica dust and requires a N95 NIOSH-approved respirator in work sites where dangerous amounts of silica dust are present